- Wheel Mucking Loader

- Wheel Mucking Loader Standard Type

- Wheel Mucking Loader LWT- 50

- Wheel Mucking Loader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Mucking Loader Enhanced Type

- Wheel Mucking Loader LWT- 60

- Wheel Haggloader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Haggloader LWT- 80

- Wheel Mucking Loader Heavy Type

- Wheel Mucking Loader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Mucking Loader with Scraper

- Wheel Mucking Loader with Scraper LWT- 60

- Wheel Mucking Loader with Scraper LWT- 80

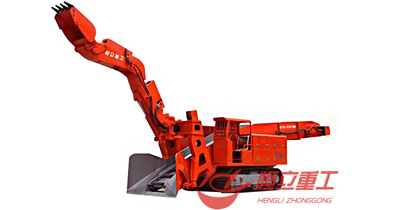

- Crawler Mucking Loader

- Crawler Mucking Loader LWL- 60 30L

- Crawler Mucking Loader LWL- 80 45L

- Crawler Mucking Loader LWL- 100 45L

- Crawler Mucking Loader LWL- 120 55L

- Crawler Mucking Loader LWL- 150 55L

- Crawler Mucking Loader LWL- 180 79L

- Big Slope Crawler Mucking Loader ZWL- 220 75L

- Special Model Mucking Loader

- Wheel Mucking Loader Standard Type LWT- 60

- Wheel Mucking Loader Folding Type LWT- 50

- Belt Crawler Mucking Loader LWT- 60

- Mucking Loader with Three Arm and Hammer

- Mining Loader

- Mining Loader HL920A

- Mining Loader HL920

- Mining Loader HL926

- Mining Loader HL928

- Mining Loader HL936

- LHD Loader/Scooptram

- LHD Loader Electrical

- LHD Loader Electrical HLWJ1.0

- LHD Loader Electrical HLWJ2.0

- LHD Loader Electrical HLWJ3.0

- Diesel LHD Loader

- Diesel LHD loader HLWJD1.0

- Diesel LHD loader HLWJD2.0

- Diesel LHD loader HLWJD3.0

- Mining Wagon/Underground Dump Truck

- Four Wheel Mining Wagon

- Four Wheel Mining Wagon UK-3

- Four Wheel Mining Wagon UK-5

- Four Wheel Mining Wagon UK-8

- Side Dumping Wagon

- Bent-rail Side-dump Mining Truck HL-FDKC

The crawler mucking loader is also known as tyre belt haggloader. As the main mining and tunnel equipment manufacturer in China, we mainly provide two kinds of crawler mucking loader for clients worldwide: crawler mucking loader for big slopes and crawler mucking loader for level surfaces. Our crawler mucking loader series is designed for high production, low cost-per-ton loading and tramming in underground mining applications.

Crawler mucking loader (mucking loader) is a highly-efficient mucking device which can work continuously. Crawler mucking loader is mainly used for loading operations during the tunneling in coal rock gangways, phosphate rock gangways, iron rock gangways, copper rock gangways, gold rock gangways, and main mine tunnels and the construction of diversion caves, tunnels and kilns. Our crawler mucking loader is applicable to tunnels with a section of above 2.4X2.4 and a gradient of ≤30°.

The predecessors of the series of big-slope crawler mining mucking loader are digging arm loader. It is chiefly used for the construction of railway tunnels, water tunnels and various mine tunnels. The company has repeatedly developed varieties and upgraded products according to the characteristics of coal mine rock gangways and non-coal-mine main laneways. This device can adapt to different environments, including construction sites with a section of 4x4m to 9x9m (width × height) and a slope of less than 32°. The main characteristics of device: using an electric hydraulic control system; using the static upper-mucking way for its working mechanism; small mucking resistance; achieving continuous and clean mucking through the scraper conveyor; achieving tunnel face risk elimination through working arm; a certain depth of mucking ditch and down-cutting surface creates conditions for rail laying.

Crawler mucking loader shovels rocks through crawler propulsion and rakes rocks into its own scraper conveyor with a bucket. The conveyor unloads rocks onto a side-dump mining wagon, skip bucket, belt conveyor, shuttle mining wagon and other loading devices from their tail.

Crawler mucking loader uses a fully hydraulic control system, and uses a reduced voltage starting way for its electrical system, suitable for the construction of long-tunnel working condition. Crawler mucking loader has a hydraulic system based on optimized design, and its major motions are controlled by the pilot valve, thus making operation easier and simpler. Crawler mucking loader works steadily without any impact. By drawing on the mature design idea and configuration of excavator, crawler mucking loader uses imported modules, multi-channel precision oil filters, and air-cooled radiators;

When using crawler mucking loader, rocks can be loaded across the section without leaving behind any dead corner, and without needing manual assistance to clear the working plane;

Chain scrape plate style is used to transport mucks, and the transportation operates steadily, with a strong mucking capacity. In addition, a semi-closed assembling way is used, thus making maintenance convenient.

Hydraulic System

Based on continuous upgrading of mucking loader, the hydraulic system is designed reasonably as a whole, and domestic and overseas famous brands are selected for all major parts, ensuring the working stability;

Secondary control is used for the hydraulic system, and it is equipped with imported hydraulic pilot control lever, with a desirable percentage control;

The hydraulic system can be selectively equipped with a purely imported load feedback system;

The hydraulic system uses a large-power air-cooling radiator, ensuring the constant oil temperature of the entire system work;

Precision filters can effectively control the pollution of hydraulic system, thus protecting oil pump and other hydraulic components and enhancing the cleanness of hydraulic system.

Working Arms

By adjusting the big-arm and small-arm structures on the spot, we can easily adjust our mucking loader to different work sections. Our wheel mucking loader has three arms for selection: standard arm, reinforced arm, and heavy arm.

Our mucking loader using a detached gantry for connection with the conveyor trough, the machine can shorten the distance between the gyration center of working arms and the material inlet, exert the work scope of arms to the maximum,and raise the risk-elimination height of arms.

Such parts as scraper ground plate, side plate and reinforced plate of wear-resistant bucket are all made of war-resistant materials, thus decreasing the friction resistance of side wall of bucket, reducing loss, and improving the durability of bucket. Bucket gears are made of special forge materials for excavator, with a desirable interchangeability.

Big-section box design is used for all working arms of our mucking loader, and various major load-carrying parts are reinforced. All concentrated parts of stress are reinforced with steel plate welding, thus becoming more reliable during high-hardness rock operations.

Chassis

Front installation is used for traveling hydraulic motors, thus reducing the load of guide wheel to strained mechanism while going uphill, thus increasing the service life.

The crawler plate is a high single-tooth plate, with a strong ground-holding ability, and increasing friction with the ground, reducing the specific pressure of grounding, and promoting climbing ability and traveling stability.

According to different working conditions of users, the interior width of crawler can be widened, and the ground clearance is heightened.

The rack is of box structure, with a large rigidity, and with a very high anti-bending and anti-torque performance under big loads, thus considerably reinforcing work stability. The even bisection way is used for the structure, and a high-strength rust-proof bolt is used for connection, thus preventing big volume from affecting underground transport.

Transporting Trough Body

High-rigidity materials are used for welding, and imported anti-resistant base plates are also used, thus increasing the service life. The entire base plate of transporting trough is based on a design idea of arc shape, thus ensuring the normal transport of rocks with a rigidity of f≤18°;

The design of the shovel mouth of transporting trough gives full play to the effect of material collection and feeding. The trough is a subsection type, and all subsections are connected with high-strength rust-proof bolts, and the descent into the well will not be affected due to length.

According to our many years of field experience, our company has designed many types of scrapers to suit different working conditions;

If a large mucking device is installed later, we can customize a special transporting trough (with an increased unloading height and an increased unloading distance), thus maximizing the transport effectiveness and efficiency;

Driving Cab

The driving cab enjoys such advantages as simple and easy operation, sensitive control, reliable work and safe riding. It has comfortable seats with a big and broad back and a full supporting capacity. It also contains automatic contraction-type safety belts, and a pedal space bigger than that of traditional mucking loader, thus ensuring a comfortable operating space. The driving cab of high-strength steel plate is firm and safe, with an extremely high anti-load and anti-drop ability. It also has a reasonably-designed structure and an omni-directional broad vision.

Diesel Power

Diesel power of our crawler mucking loader includes two forms, both of which offer a strong flexibility to devices. A small-power diesel engine is used only for traveling. If a big-power diesel engine is needed for traveling and working, this form needs to be proposed by users particularly.