- Wheel Mucking Loader

- Wheel Mucking Loader Standard Type

- Wheel Mucking Loader LWT- 50

- Wheel Mucking Loader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Mucking Loader Enhanced Type

- Wheel Mucking Loader LWT- 60

- Wheel Haggloader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Haggloader LWT- 80

- Wheel Mucking Loader Heavy Type

- Wheel Mucking Loader LWT- 60

- Wheel Mucking Loader LWT- 80

- Wheel Mucking Loader with Scraper

- Wheel Mucking Loader with Scraper LWT- 60

- Wheel Mucking Loader with Scraper LWT- 80

- Crawler Mucking Loader

- Crawler Mucking Loader LWL- 60 30L

- Crawler Mucking Loader LWL- 80 45L

- Crawler Mucking Loader LWL- 100 45L

- Crawler Mucking Loader LWL- 120 55L

- Crawler Mucking Loader LWL- 150 55L

- Crawler Mucking Loader LWL- 180 79L

- Big Slope Crawler Mucking Loader ZWL- 220 75L

- Special Model Mucking Loader

- Wheel Mucking Loader Standard Type LWT- 60

- Wheel Mucking Loader Folding Type LWT- 50

- Belt Crawler Mucking Loader LWT- 60

- Mucking Loader with Three Arm and Hammer

- Mining Loader

- Mining Loader HL920A

- Mining Loader HL920

- Mining Loader HL926

- Mining Loader HL928

- Mining Loader HL936

- LHD Loader/Scooptram

- LHD Loader Electrical

- LHD Loader Electrical HLWJ1.0

- LHD Loader Electrical HLWJ2.0

- LHD Loader Electrical HLWJ3.0

- Diesel LHD Loader

- Diesel LHD loader HLWJD1.0

- Diesel LHD loader HLWJD2.0

- Diesel LHD loader HLWJD3.0

- Mining Wagon/Underground Dump Truck

- Four Wheel Mining Wagon

- Four Wheel Mining Wagon UK-3

- Four Wheel Mining Wagon UK-5

- Four Wheel Mining Wagon UK-8

- Side Dumping Wagon

- Bent-rail Side-dump Mining Truck HL-FDKC

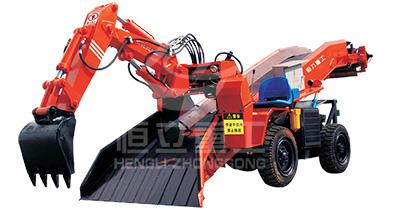

The wheel mucking loader, also known as wheel haggloader or wheel tunnel excavator, is a type of underground mining equipment.

Wheel excavation loader (mucking loader) is applicable to the construction of tunnel, mine, water conservancy and other projects and the mucking of small-section diversion caves and mines. This machine is mainly used to collect, transport and load grave soil of mines and tunnels. Wheel Mucking Loader is an indispensible advanced mining device for mine and tunnel construction, and is a substitute product of labor and other machinery.

Combining the manipulator and the conveyor, and integrating collection and transport functions, wheel excavation loader (mucking loader) is controlled by a fully hydraulic system, and is characterized by safety, environmental friendliness, small energy consumption and high efficiency. With an excellent humanized design, our wheel mucking loader can enormously reduce workers’ labor intensity, characterized by a high speed of transport, safety and reliability, environmental friendliness, high efficiency, and high economization on manpower.

As a powerful manufacturer of mining equipment, Hengli can add a folding type to all its wheel mucking loaders. Moreover, all non-explosion-proof wheel mucking loaders are accompanied by a diesel engine, and can travel with auxiliary oil pipes without being connected with cables, thus becoming a dual-power mucking loader. Our factory can add a one-key-start function which can directly start the diesel engine without hand-cranking. This function can also be added to all non-explosion-proof models.

Working Arms

By adjusting the big-arm and small-arm structures on the spot, we can easily adjust our mucking loader to different work sections. Our wheel mucking loader has three arms for selection: standard arm, reinforced arm, and heavy arm.

Our mucking loader using a detached gantry for connection with the conveyor trough, the machine can shorten the distance between the gyration center of working arms and the material inlet, exert the work scope of arms to the maximum,and raise the risk-elimination height of arms.

Such parts as scraper ground plate, side plate and reinforced plate of wear-resistant bucket are all made of war-resistant materials, thus decreasing the friction resistance of side wall of bucket, reducing loss, and improving the durability of bucket. Bucket gears are made of special forge materials for excavator, with a desirable interchangeability.

Big-section box design is used for all working arms of our mucking loader, and various major load-carrying parts are reinforced. All concentrated parts of stress are reinforced with steel plate welding, thus becoming more reliable during high-hardness rock operations.

Folding Legs

According to different conditions of mine cave sections, folding style mucking loader is used for the tail output system. There are two oil cylinder supports during operations, thus reaching a desirable mucking effect, and they can be folded during non-operations, without occupying any space;

When the mucking loader cannot turn around conveniently due to narrowness of working section, the folding legs can be contracted, thus reducing the length of machine body, enabling the mucking loader to pass through normally, and enhancing operating efficiency.

Ingenious and compact folding leg design fully embodies that the mucking loader adapts to the transport mucking effect in underground special environment. Based on many times of variety development and product upgrading, our mucking machine series products can adapt to different environments.

Diesel Engine

Wheel excavation loader (mucking loader) has two ways of travel: one is electric travel; the other is diesel engine assisted travel;

A diesel engine of domestic and overseas famous brand is used, and one-key-start is also used, thus bringing convenience and saving time. If it is inconvenient to use electricity in mine caves, the diesel engine power can be used to assist the travel, thus avoiding the trouble of connection with cables, and enhancing operating efficiency.